China Rapid Prototype Service: Transforming the Landscape of Manufacturing

In the fast-paced world of manufacturing, staying ahead of the competition is crucial. One effective way to achieve this is through the adoption of china rapid prototype service. This innovative service is not just a trend; it represents a significant advancement in how products are designed, tested, and brought to market. In this comprehensive article, we will explore the depths of rapid prototyping, its methods, benefits, and its integral role specifically for metal fabricators.

Understanding Rapid Prototyping

Rapid prototyping is a set of techniques used to quickly create a scale model or functional part of a physical object. This process allows businesses to visualize and test their ideas before committing to full-scale production. With the rise of advanced technologies, particularly in China, rapid prototyping services have become increasingly accessible and sophisticated.

Key Technologies Behind Rapid Prototyping

Several cutting-edge technologies are utilized in the process of rapid prototyping, including:

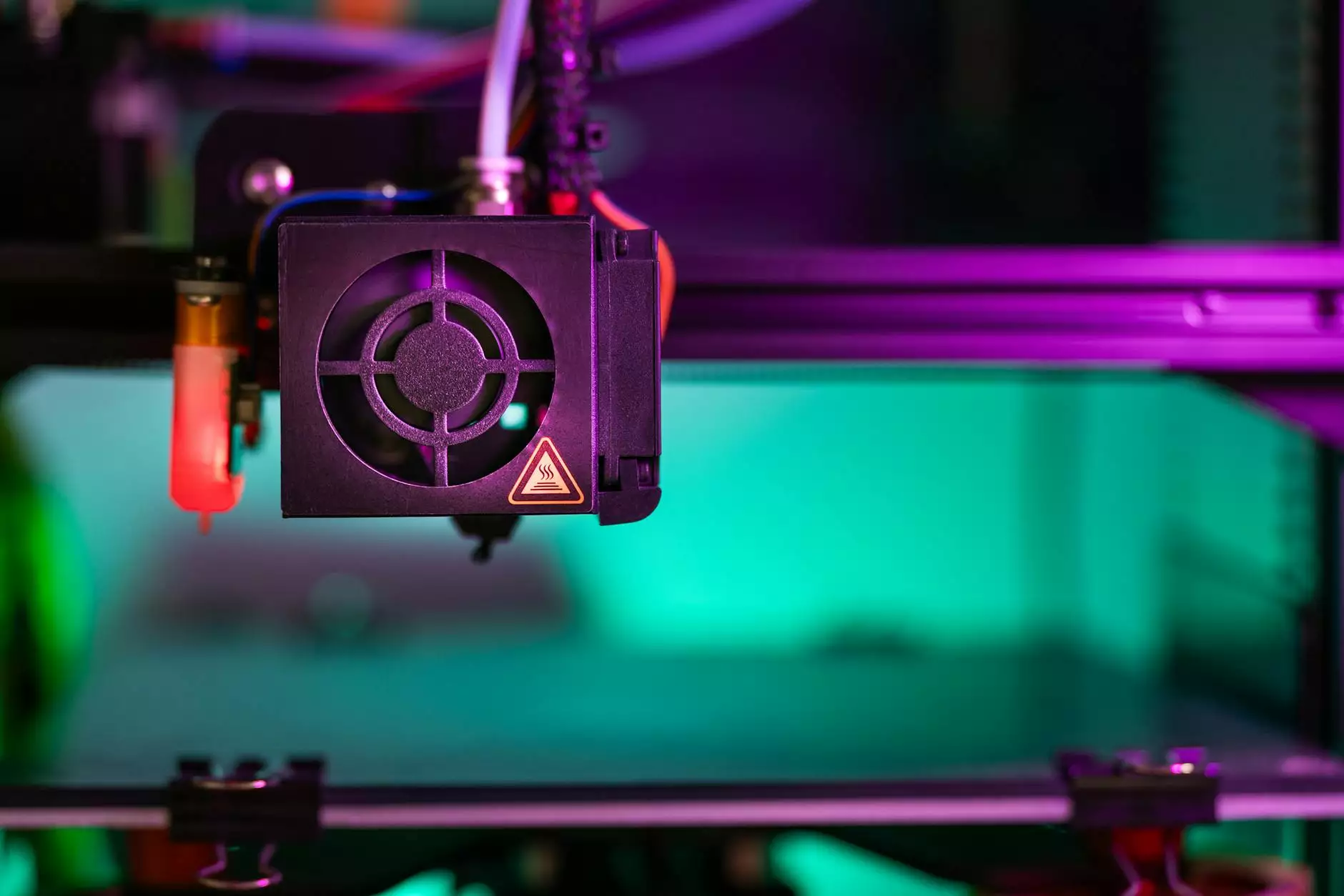

- 3D Printing (Additive Manufacturing): This technique builds objects layer by layer from digital models, enabling complex geometries and custom designs.

- CNC Machining: Using computer-controlled machines, this method produces precise prototypes from solid blocks of material.

- Vacuum Casting: This process involves creating silicone molds for low-volume production, ideal for testing products before large-scale manufacturing.

- SLA (Stereolithography): A form of 3D printing that uses UV light to cure liquid resin into solid objects, providing a high level of detail and smooth finishes.

The Advantages of China Rapid Prototype Service

The benefits of utilizing a china rapid prototype service are numerous, especially for metal fabricators who are often under pressure to deliver quality products efficiently. Here are some of the most significant advantages:

1. Speed to Market

One of the primary benefits of rapid prototyping is the reduction in time to market. Prototypes can be developed within days or weeks rather than months, allowing companies to respond quickly to customer demands and market changes. This speed is essential for maintaining a competitive edge.

2. Cost Efficiency

Creating a prototype using traditional manufacturing methods can be costly and resource-intensive. In contrast, rapid prototyping reduces waste and minimizes the costs associated with materials and labor. For metal fabricators, this means significant savings while maintaining product quality.

3. Enhanced Communication

Prototypes serve as a tangible representation of ideas, facilitating better communication among stakeholders. Whether it’s between designers, engineers, or clients, having a physical product to discuss leads to clearer understanding and collaborative improvements.

4. Iterative Design Process

Rapid prototyping encourages an iterative approach to product development. This flexibility allows for easy modifications and refinements to design based on testing feedback, resulting in better end products that meet market needs effectively.

5. Risk Mitigation

Testing a prototype before full-scale production helps identify potential issues early in the process. With a china rapid prototype service, manufacturers can assess functionality, design flaws, and user interactions, significantly reducing the risks associated with product launches.

Applications of Rapid Prototyping in Metal Fabrication

Metal fabricators are in a unique position to benefit from rapid prototyping. Here are some specific applications:

1. Custom Parts Production

With the growing demand for customized products, metal fabricators can leverage rapid prototyping to produce tailored components. Whether it's a specialized automotive part or a unique assembly for machinery, rapid prototyping can facilitate fast yet precise production.

2. Tooling and Fixtures Development

Prototyping is essential for creating complex tools and fixtures required in manufacturing processes. Rapid prototype services allow fabricators to develop and test their designs efficiently, ensuring they meet operational requirements and performance standards.

3. Product Testing and Validation

The ability to create prototypes enables metal fabricators to test their designs under real-world conditions. This leads to better validation processes, ensuring that products will function as intended once they enter the market.

Choosing the Right China Rapid Prototype Service

With numerous providers available, selecting the right china rapid prototype service can be challenging. Here are key factors to consider:

- Experience and Expertise: Look for providers with substantial experience and a portfolio of successful projects.

- Technology Offerings: Evaluate the range of technologies they use and their suitability for your specific needs.

- Turnaround Time: Ensure that the company can meet your timeline requirements while maintaining quality.

- Customer Support: Select a service that offers robust customer support throughout the prototyping process.

Case Studies: Successful Implementation of Rapid Prototyping

To better illustrate the impact of rapid prototyping on metal fabrication, let’s look at some real-world examples.

Case Study 1: Automotive Industry

One major automotive manufacturer incorporated rapid prototyping into their design process. By utilizing advanced 3D printing technology, they were able to develop and test new engine components in a matter of weeks, rather than months. This resulted in faster development cycles and lower costs, all while ensuring that the components met stringent industry standards.

Case Study 2: Aerospace Sector

A leading aerospace fabricator faced strict compliance and performance testing requirements. By leveraging rapid prototyping, they could create high-precision parts and conduct thorough validation tests rapidly. The iterative prototyping process allowed them to refine the designs continually, leading to enhanced safety and better overall performance without the excessive costs traditionally associated with aerospace manufacturing.

Future Trends in Rapid Prototyping

The rapid prototyping industry is evolving, and several trends are shaping its future:

1. Integration of AI and Machine Learning

Artificial intelligence is increasingly being integrated into the prototyping process, optimizing designs and predicting potential issues before they arise. This leads to further enhancements in efficiency and effectiveness.

2. Sustainability Practices

As industries shift toward sustainable practices, rapid prototyping is adapting. New techniques that minimize waste and use eco-friendly materials are emerging, allowing fabricators to align with global sustainability goals.

3. Advanced Materials Development

With constant research and development, the variety of materials available for rapid prototyping is expanding. Innovations in metals, polymers, and composites will enable more varied applications and improved product performance.

Conclusion

In conclusion, the china rapid prototype service stands out as an invaluable asset to the manufacturing sector, particularly for metal fabricators seeking to innovate and improve their production processes. The speed, cost-effectiveness, and iterative design opportunity it offers cannot be overstated. As industries continue to evolve, those who embrace rapid prototyping will undoubtedly position themselves as leaders in their respective fields.

By leveraging the advantages of rapid prototyping, businesses can not only meet customer expectations but also set new standards for quality and efficiency. The future of manufacturing lies in innovation, and rapid prototyping is at the forefront of this revolution.